Reimagine growth at Elevate – Dallas 2025. See the Agenda.

Filter

Displaying 51-60 of 530

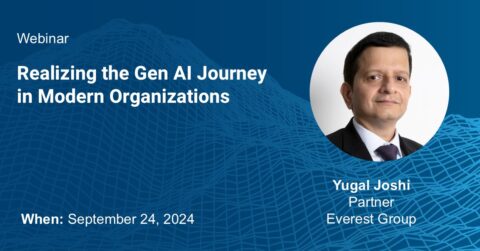

Realizing the Gen AI Journey in Modern Organizations | Webinar

September 24, 2024

09:30 AM PT | 12:30 PM ET

Webinar

Elevating Talent Experience with Automation and Workflows | Webinar

September 25, 2024

1:30 - 2:30 PM ET

Webinar