Technological Advances in Sustainable Packaging and Its Role in a Circular Economy | Blog

As global environmental mandates escalate and consumers demand sustainable practices, packaging has emerged as a vital lever in the pursuit of circularity. Once seen as a disposable necessity, packaging is now a strategic enabler of climate resilience, brand responsibility, and supply chain efficiency.

In our latest report, Technological Advances in Sustainable Packaging and Its Role in a Circular Economy, we examine how innovation in materials, intelligent design, and ecosystem alignment is driving a fundamental shift in packaging systems, turning waste into resource and linearity into loops.

Macro forces catalyzing packaging innovation

Today’s packaging transformation is being shaped by a convergence of macroeconomic, regulatory, and behavioral forces:

- Evolving regulations: From extended producer responsibility (EPR) schemes to mandates on recyclability and compostability, governments are tightening requirements.

- Consumer expectations: Buyers are holding brands accountable for sustainability, from transparent labeling to reusable or minimal-impact packaging.

- Sustainability targets: Corporations are now factoring packaging into their carbon accounting and net-zero strategies, often under pressure from investors and watchdogs.

These intersecting forces are creating both urgency and opportunity for innovation across the packaging value chain.

Material innovation: Engineered for circularity

Material science is at the forefront of packaging’s sustainable reinvention. Four categories of materials are gaining traction:

- Bio-based polymers: Sourced from renewable biomass such as sugarcane, seaweed, or algae, these polymers reduce dependence on fossil-based plastics while offering performance parity.

- Mono-material laminates: Designed for recycling, these materials simplify recovery by eliminating multi-layer compositions that hinder separation.

- Compostable films & fiber composites: Offering end-of-life benefits through industrial and home compostability, they strike a balance between functionality and biodegradation.

- Advanced degradation technologies: Enzymatic depolymerization and microbial detoxification are enabling new pathways for safe, accelerated breakdown of packaging waste.

These innovations align with a “design for end-of-life” philosophy, supporting the shift from linear to circular material flows.

Smart packaging: Where intelligence meets sustainability

Smart packaging is no longer futuristic; it’s a practical enabler of circularity:

- Digital watermarks & embedded codes: Enhance sorting accuracy and enable automated material separation at recycling facilities.

- Sensors & trackers: Monitor product integrity, extend shelf life, and support closed-loop logistics systems.

- Reusable & traceable logistics packaging: Enables businesses to deploy returnable assets across supply chains with full visibility and improved lifecycle economics.

These advancements not only optimize sustainability but also unlock new data insights and operational efficiencies.

Ecosystem coordination: From pilot to scale

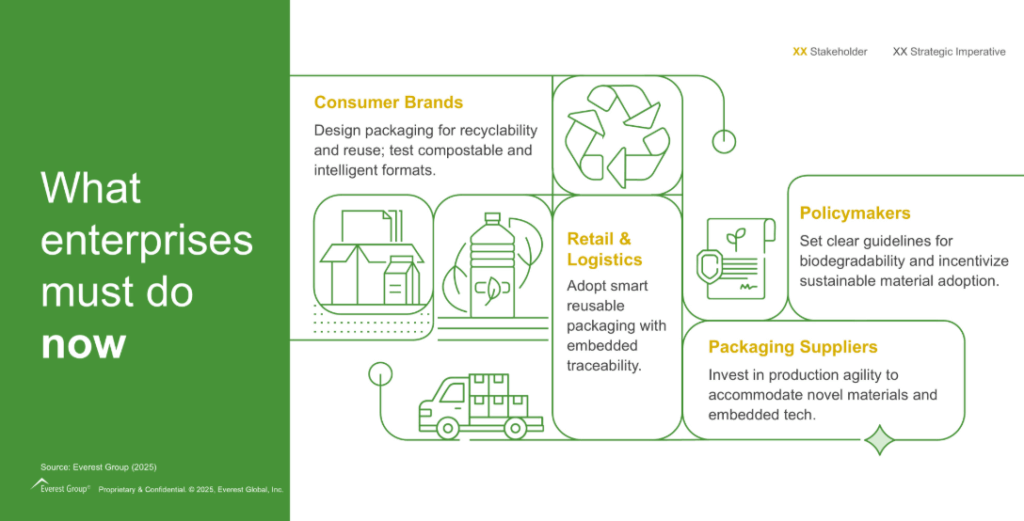

Our report takes a holistic, ecosystem-based view, recognizing that packaging doesn’t exist in isolation. Success requires alignment across:

- Brands and manufacturers – Rethinking packaging design and investing in flexible production infrastructure.

- Recyclers and waste managers – Upgrading capabilities to sort and process new material formats.

- Policy makers and regulators – Harmonizing standards to encourage innovation while ensuring accountability.

- Consumers – Playing an active role in disposal, reuse, and demand for responsible alternatives.

We profile real-world case studies where these stakeholders are already collaborating effectively to bring sustainable packaging to scale.

What enterprises must do now

Turning insights into action

For Everest Group clients, this report offers a strategic roadmap:

- Sustainability leaders: Understand which material and digital strategies yield the highest ROI on ESG targets.

- Packaging and R&D heads: Prioritize high-readiness solutions and build pilot pipelines.

- Supply chain executives: Assess reuse models and smart packaging opportunities that can cut costs and waste.

Looking ahead

The packaging industry is reaching an inflection point. With the right mix of innovation, collaboration, and policy support, packaging can evolve from environmental liability to regenerative assets. But the window for passive observation is closing, leaders must act now to design packaging systems that are smart, circular, and future-ready.

The full report, Technological Advances in Sustainable Packaging and Its Role in a Circular Economy, is available now and includes:

- Ecosystem adoption frameworks

- Maturity readiness heatmaps

- Case studies from early movers

- Strategic implementation checklists

Read more at: Technological Advances in Sustainable Packaging and its Role in a Circular Economy – Everest Group Research Portal